Behind the walls of Florida’s only lead smelter | Investigations

GoogleAds

A collage of videos from inside Gopher Resource.

[ Factory videos taken by Gopher workers ]

Workers shared photos and videos chronicling long-standing problems at the Tampa factory.

What’s it like inside Florida’s only lead smelter? Tampa Bay Times reporters obtained from current and former workers hundreds of photos and videos taken at the factory where 50,000 used car batteries are recycled each day. The lead is melted down and reforged into new blocks. The work can be dirty and each step comes with its own hazards. Many of these images show workers in unclean and dangerous conditions, sometimes narrowly escaping serious injury. Here is a collection of some of them:

The raw materials processing center

At Gopher Resource in Tampa, battery recycling works in multiple stages. First, machines remove lead from batteries and separate it from other components, like the plastic shells and acid. To start the process, workers load batteries into a hammermill, which crushes them.

Batteries travel along this conveyor to be crushed in the hammermill. Photo taken in 2014.

[ Photograph by a Gopher worker ]

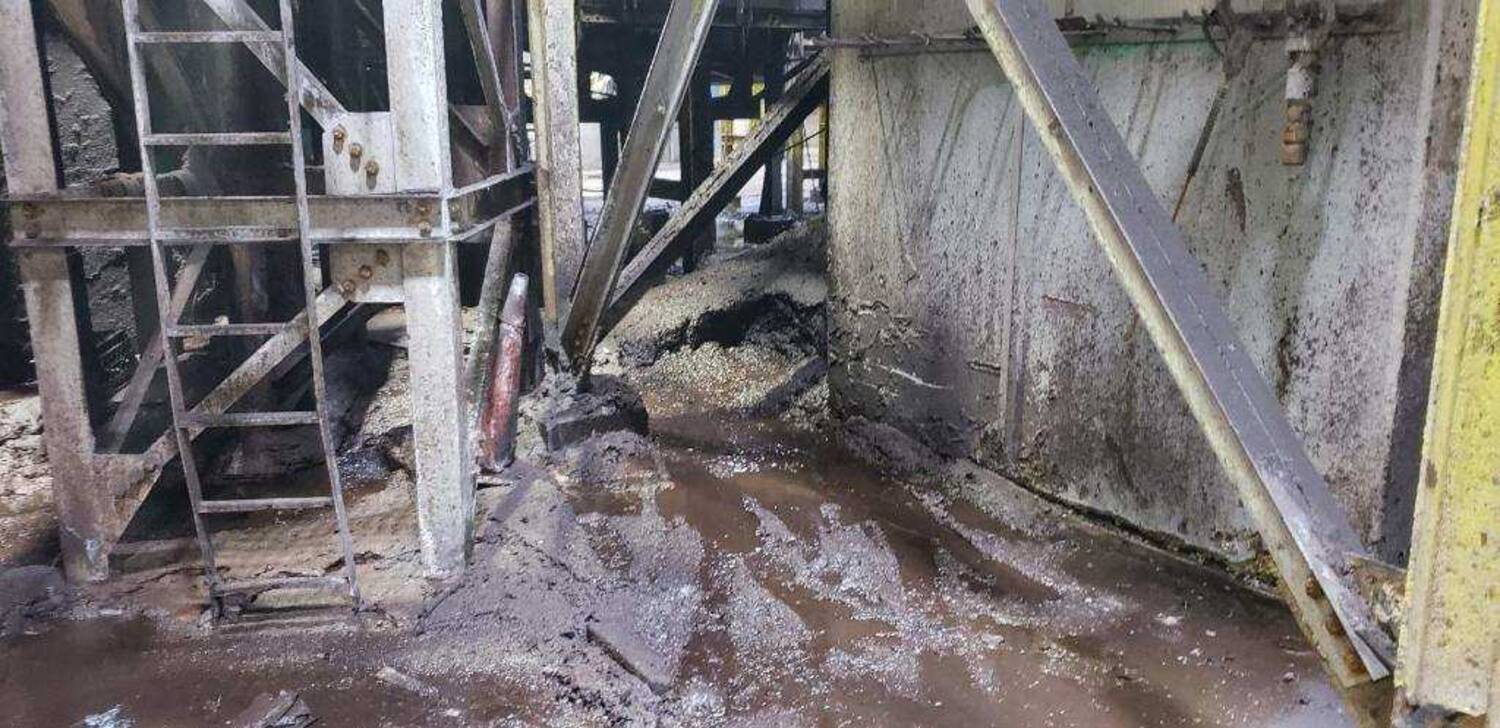

As lead is being retrieved from the broken batteries, pieces of plastic, acid and lead often fall to the ground, landing in areas underneath the equipment. Federal rules require the cleaning of this residue to prevent injury and contamination. For the past eight months, however, the battery waste went unaddressed.

Lead mud accumulates beneath the area where batteries are broken down in July 2020. Photo taken in July 2020.

[ Photograph by a Gopher worker ]

Plastic battery shells sit in acid-soaked, lead-laced mud below the battery breaking equipment. Photo taken March 29, 2021.

[ Photograph by a Gopher worker ]

Lead-contaminated sludge builds up below the mezzanine where batteries are crushed. Photo taken March 29, 2021.

[ Photograph by a Gopher worker ]

But when OSHA showed up on April 5, the area was much cleaner. Workers had shoveled the sludge over the weekend.

This photo shows the condition of the area below the hammermill, which crushes the old car batteries, as it appeared when OSHA walked through the area. Photo taken in April 2021.

[ Photograph by a Gopher worker ]

The mud — which had plagued the area for months — had been removed in time for OSHA’s visit. Photo taken in April 2021.

[ Photograph by a Gopher worker ]

In another area of the raw materials processing center, called the battery-breaking room, large industrial batteries are cracked open over a metal plate. Stagnant acid had eaten at the concrete floor, causing significant damage. Potholes caused by the acid and battery-breaking created a hazard for forklift drivers who needed to maneuver in and out of the room. Workers have fallen because it’s so slippery. Gopher began work on a new floor just days before OSHA inspectors showed up for the first time in five years.

The battery acid mixes with lead dust to create an acidic sludge that has eaten away at the floor in the battery breaking room, where industrial batteries are smashed open on this metal plate. Photo taken in late March 2021.

[ Photograph by a Gopher worker ]

A pool of what workers said was acid sits stagnant on the floor of the industrial room. Video taken in 2019.

A worker slips on the acid-soaked floor of the industrial room. Video taken in 2018.

Video by a Gopher worker

The furnace

After lead is salvaged from batteries, workers use loader trucks to scoop the metal and feed it into furnaces, which are heated to around 1,500 degrees. The lead is liquified here and some impurities are separated from the molten metal. The furnace department is the dustiest area of the plant, recording air-lead levels hundreds of times above the federal limit in recent years. Fumes have spewed from the furnaces into the workspace, escaping from inadequate ventilation. The ventilation system has suffered from clogged pipes and exhaust hoods that were too small. Dust has accumulated in areas above the furnace, dropping suddenly like an eruption of ash and scorching workers below.

The furnace glows bright orange while lead is melted. Photo taken in 2017.

[ Photograph by a Gopher worker ]

Lead-containing rock called “slag” and other raw materials are stored in the containment room before being fed into the furnaces. The room is filled with dust, which is kicked up during work and clouds the air. Photo taken in April 2021.

[ Photograph by a Gopher worker ]

A furnace pipe is partially clogged by dust in February 2021. This type of obstruction can hamper the ventilation system’s ability to remove poisons from the workplace air. Workers say the pipes have rarely been cleaned. Gopher started pipe upgrades after receiving questions from the Times about mechanical problems and worker exposures.

[ Photograph by a Gopher worker ]

Slag piles up in front of a door, near the area where the material is collected. A broom sits next to the pile. OSHA discourages the use of brooms and shovels to clean floors because they kick up dust. The preferred method is to use a vacuum with appropriate filters. Photo taken in April 2021.

[ Photograph by a Gopher worker ]

Images from the furnace department show how bad the dust storms can get inside the factory. In some cases, the dust and fumes have become so thick that visibility is reduced to almost zero, creating near white-out like conditions.

Fumes from the reverberatory furnace escape into the work area. Photo taken in July 2020.

[ Photograph by a Gopher worker ]

Dust hangs in the air in the containment room. Photo taken in July 2020.

[ Photograph by a Gopher worker ]

Dust creates a haze throughout the containment room as workers drive loader trucks, some without enclosed cabs. Photo taken in July 2020.

[ Photograph by a Gopher worker ]

The glow of the reverberatory furnace can be seen through a haze of fumes. Photo taken in July 2020.

[ Photograph by a Gopher worker ]

Dust collects on a ventilation pipe overhead in the furnace department. Photo taken in 2020.

[ Photograph by a Gopher worker ]

Fumes billow out from the reverberatory furnace and into the workspace. Video taken in 2020.

Video by a Gopher worker

An afterburner in the furnace department has been associated with lead dust explosions for years. The eruptions, commonly called “dust drops” among workers, occur without warning and spray clouds of hot lead particles. In this October 2019 video, a maintenance worker’s hands and arms were scorched by the explosion. A year later, a dust drop severely burned the leg of a different employee. Video taken in 2019.

Video by a Gopher worker

A gray haze of lead dust reduces visibility in the furnace department. Video taken in 2019.

Video by a Gopher worker

A lead-dust avalanche falls in the furnace department. Video taken in 2019.

Video by a Gopher worker

A forklift driver moves pots filled with slag, a byproduct created when lead is melted in the furnaces. The vehicle hits a doorway and the pots fall, sparking a fiery explosion. Video taken in 2014.

Video by a Gopher worker

The refinery

Molten lead from the furnace glides through chutes into kettles in the refinery. Workers mix in chemicals, such as sulfur and sodium nitrate. Impurities float to the top where workers skim off the byproduct and sometimes get hit by a shot of fumes. The byproduct is shoveled into containers and later sold to another company for further processing. Videos have shown the liquid metal becoming volatile in the kettles, thrashing like rough ocean water. Sometimes, explosions occur and send the molten lead flying. After refining, the liquid lead is poured into molds and cooled to form solid blocks that are sold.

A worker shovels calcium into a kettle in the refinery. Video taken in 2015.

A kettle erupts after a refinery worker inserts a chemical substance to help remove impurities from the molten lead. Video taken in 2018.

Video by a Gopher worker

A dust explosion occurs in the area between the refinery and furnace. Video taken in 2017.

Video by a Gopher worker

A torch bursts in the refinery. Since 2012, several workers have been burned due to faulty blow torches, according to safety reports and company emails. Video taken in 2017.

Video by a Gopher worker

A stack of lead blocks sits on a conveyor in the refinery area. Photo taken in 2017.

[ Photograph by a Gopher worker ]

A worker is hit with fumes while removing impurities from a kettle of molten lead in the refinery. Video taken in 2014.

Video by a Gopher worker

Molten lead grows volatile inside a kettle and spews into the work area, sending a worker running. Video taken in 2014.

Video by a Gopher worker

Lead is caked on a kettle in the plant’s refining department. Photo taken in 2014.

[ Photograph by a Gopher worker ]

The baghouse

Throughout the process, dust and fumes are sucked into the plant’s ventilation system and routed to the baghouse, which captures the dust before it can be released into the atmosphere. The baghouse has a grid of rooms called cells. The dirty air or gas stream enters from the bottom of the cell and flows through bags that hang floor-to-ceiling. The bags catch and filter contaminated particles. The bags must be shaken regularly to clean the dust out of them. The dust then falls into a hopper below and is conveyed for further processing. Workers have had to manually shake the bags when the automated system went down, causing them to enter the small rooms sometimes overwhelmed by dust and gases. Some workers passed out, either from extreme heat or fumes, after trips inside. When other mechanical systems have gone down, they’ve had to shovel contaminated dust from mounds beneath the baghouse that looked like small sand dunes.

The baghouse cells are accessed through these doors. Dust is piped into the rooms. At times, workers have had to enter the cells to shake bags full of lead when the automated shaking system malfunctioned or other problems occured.

[ Photograph by a Gopher worker ]

Bags designed to capture lead dust hang floor-to-ceiling in the baghouse. These are the bags that had to be manually shaken when the automated shaking feature broke down. At times, workers left the cells so covered in dust, they looked like ghosts. Photo taken in 2016.

[ Photograph by a Gopher worker ]

Mounds of dust pile up in the baghouse area. Photo taken in 2015.

[ Photograph by a Gopher worker ]

Lead dust swirls around a worker in the baghouse. Video taken in 2015.

Video by a Gopher worker

Dust billows from a pipe, creating a cloud across the workspace in the baghouse. Workers drive un-enclosed forklifts through the dust to collect it. Video taken in 2014.

Video by a Gopher worker

Mounds of dust accumulate underneath the baghouse, where workers used shovels to gather it up. Photo taken in 2014.

[ Photograph by a Gopher worker ]

Wastewater treatment

Acid and water mixed with lead dust are sent to the wastewater treatment section of the plant to be diluted and neutralized before being released into the city’s wastewater system. Problems in this section have caused harmful gas levels to spike. At least two employees have passed out in this section of the plant after being overwhelmed by fumes.

The factory has had ongoing problems with its oxidation reactors, which play a crucial role in controlling sulfur dioxide levels. When the devices malfunction, the gas levels in the plant’s air can spike. Photo taken in February 2021.

[ Photograph by a Gopher worker ]

The oxidation reactor springs a leak in the wastewater treatment department. Video taken in February 2021.

Video by a Gopher worker

Leaving the plant

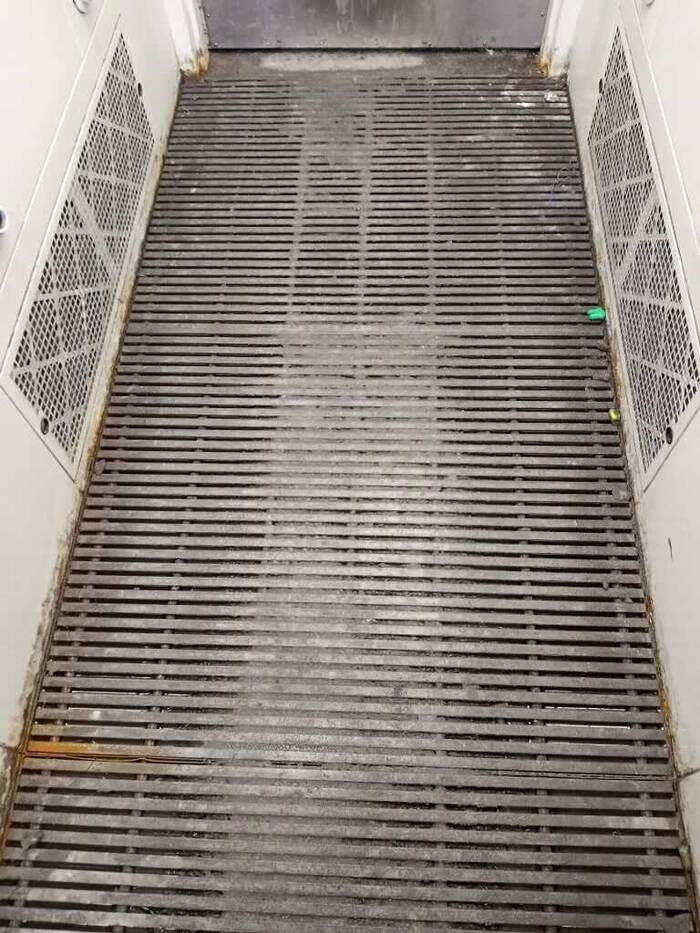

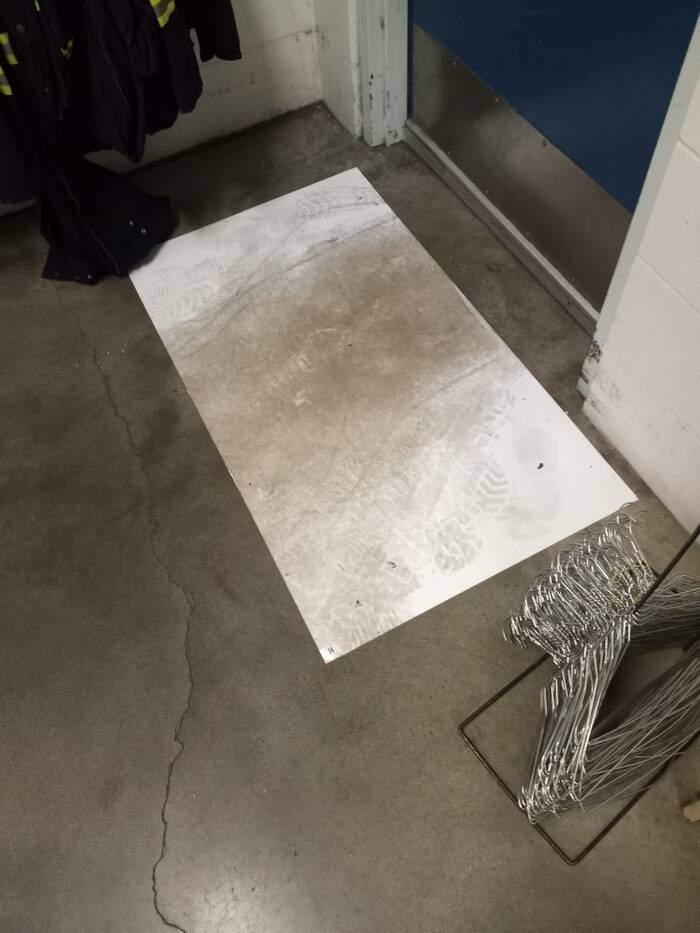

Workers must clean off after every shift. Gopher provides locker rooms in the hygiene area of the property, which is separate from the plant. Following the Times’ reporting on conditions at the factory, Gopher made fixes to lingering problems that could result in higher exposures or workers carrying lead home to their children, including placing down mats in the dirty locker room to remove lead from workers’ shoes and fixing a malfunctioning air-shower system. Gopher has said the fixes were not in response to the newsroom’s investigation.

When workers from the refinery or furnace department leave the plant, many walk through this area where air showers blow dust off their uniforms. Workers said the system had been malfunctioning but was repaired after the Times wrote about conditions at the plant. Photograph taken in April 2021.

[ Photograph by a Gopher worker ]

The company recently placed down sticky mats inside the hygiene building to pull dust from workers’ shoes. This one is located between the dirty locker room, where workers change out of their dusty uniforms, and the clean locker room where they dress in street clothes before going home. Photograph taken in April 2021.

[ Photograph by a Gopher worker ]

We want to talk with you

Do you live in the neighborhoods of Grant Park, Oak Park, Florence Villa, Dixie Farms or Uceta Gardens in Hillsborough County? And do you suffer from these health issues?

Heart ailments

Kidney disease

Infertility

Hypertension

Muscle weakness

Behavioral problems

Reduced attention span

Cognitive disabilities

Debilitating headaches

These are among the factors associated with high levels of lead exposure. Please contact us if you are interested in talking.

Source : https://projects.tampabay.com/projects/2021/investigations/lead-factory/inside-gopher-smelter-video-photos/

Auteur :

Date de Publication : 2021-04-12 09:00:00

Le droit d’auteur pour le contenu syndiqué appartient à la source liée.

GoogleAds